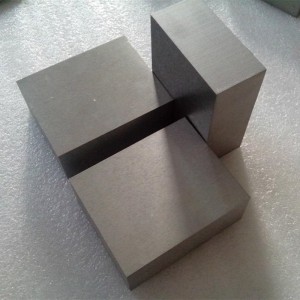

I-Silver Tungsten Alloy

Ingxubevange ye-tungsten yesiliva iyinhlanganisela engavamile yezinsimbi ezimbili eziphawulekayo, isiliva ne-tungsten, enikeza isethi eyingqayizivele yezakhiwo nezinhlelo zokusebenza.

I-alloy ihlanganisa ukuguquguquka okuhle kukagesi kwesiliva nendawo ephezulu yokuncibilika, ubulukhuni, nokumelana nokugqoka kwe-tungsten. Lokhu kuyenza ifaneleke kakhulu kwizicelo ezahlukahlukene ezidingayo emkhakheni kagesi kanye nemishini.

Embonini kagesi, i-silver tungsten alloy isetshenziswa kothintana nogesi kanye nokushintsha. Ikhono layo lokumelana nezinga lokushisa eliphezulu kanye ne-arcing liyenza ithembeke kulezi zingxenye ezibalulekile. Isibonelo, ezinhlelweni zikagesi ezinamandla amakhulu, lapho ukugeleza kwamanje kubaluleke kakhulu futhi ingozi yokushisa iphezulu, ukusetshenziswa kwe-silver tungsten alloy kuqinisekisa ukusebenza kahle nokuphephile.

Emkhakheni wemishini, ithola ukusetshenziswa kumathuluzi futhi iyafa ngenxa yokuqina nokuqina kwayo. Izingxenye ezenziwe ngale ngxubevange zingamelana nengcindezi eqinile yemishini kanye nokuguga okuhugayo, zandise isikhathi sazo sokuphila futhi zithuthukise ukusebenza.

Ukukhiqizwa kwe-silver tungsten alloy ngokuvamile kuhilela izinqubo eziyinkimbinkimbi zokufeza ukwakheka okufunayo kanye ne-microstructure. Lokhu kuqinisekisa ibhalansi efanele yezakhiwo zezinhlelo zokusebenza ezithile.

Ucwaningo nentuthuko emkhakheni wesiliva we-tungsten alloys iyaqhubeka nokuvela, ivula amathuba amasha kanye nentuthuko. Ososayensi nonjiniyela bahlala behlola izindlela zokuthuthukisa izakhiwo zayo nokwandisa ububanzi bokusebenza kwayo.

Sengiphetha, ingxubevange ye-tungsten esiliva imelela njengobufakazi bobuhlakani bomuntu kwisayensi yezinto ezibonakalayo, enikeza izixazululo kwezinye zezinkinga eziyinselele kakhulu zobunjiniyela nezobuchwepheshe. Inhlanganisela yayo eyingqayizivele yezakhiwo iyenza ibe yinto ebaluleke kakhulu ezimbonini ezahlukahlukene, ibumba umhlaba wesimanje ngokuba khona kwawo namandla.

Ukwenziwa kwe-silver tungsten alloy:

I-Powder Metallurgy:

Lena indlela evamile. Izimpushana ezinhle zesiliva ne-tungsten zixutshwa ngezilinganiso ezidingekayo. Ingxube ibe isihlanganiswa ngaphansi kwengcindezi ephezulu ukuze yakhe icwecwe eliluhlaza. Le compact ibuye ifakwe emanzini ezingeni lokushisa eliphezulu ukuze ihlanganise izinhlayiya ndawonye futhi yakhe ingxubevange eqinile. Isibonelo, kwezinye izimo, izimpushana zingase zigaywe ndawonye kuqala ukuze kuqinisekiswe ingxube efanayo.

I-Chemical Vapor Deposition (CVD):

Ngale ndlela, izandulela zegesi ezinesiliva ne-tungsten zingeniswa ekamelweni lokusabela. Ngaphansi kwezimo ezithile zokushisa nokucindezela, izandulela zisabela futhi zibeke ku-substrate ukuze zakhe ungqimba lwe-alloy. Le nqubo ivumela ukulawula okunembile kokwakheka kwe-alloy kanye ne-microstructure.

I-Electroplating:

Ingxubevange ye-tungsten yesiliva nayo ingakhiwa ngokusebenzisa i-electroplating. I-tungsten substrate icwiliswa ku-electrolyte equkethe ama-ion esiliva. Ngokusebenzisa amandla kagesi, isiliva lifakwa endaweni ye-tungsten, yakhe ungqimba lwe-alloy. Le nqubo ingashintshwa ukuze kuzuzwe ukujiya okuhlukene kanye nokuqanjwa kwe-alloy coating.

I-Sinter-HIP (Hot Isostatic Pressing):

Ingxube yempushana iqala i-sintered bese ifakwa ngaphansi kokucindezela okushisayo kwe-isostatic. Lokhu kusiza ukuqeda i-porosity futhi kuthuthukise ukuminyana kanye nezakhiwo zemishini ye-alloy eyenziwe.

Ukukhethwa kwendlela yokwenziwa kuncike ezicini ezihlukahlukene ezifana nezakhiwo ezifunwayo ze-alloy yokugcina, umumo nosayizi wengxenye ezokhiqizwa, kanye nesilinganiso sokukhiqiza. Indlela ngayinye inezinzuzo zayo kanye nemikhawulo, futhi ngokuvamile, inhlanganisela yalezi zindlela ingase isetshenziswe ukuze kuzuzwe imiphumela engcono kakhulu.

I-Silver tungsten alloy inezinhlelo zokusebenza ezimbalwa ezithile ngenxa yezakhiwo zayo ezihlukile:

Oxhumana Nabo Kagesi:

● Kuma-circuit breaker ane-voltage ephezulu, lapho ekwazi ukuphatha amaza amakhulu nokushintshashintsha njalo ngaphandle kokuguga okuphawulekayo noma ukuwohloka.

● Kuma-relay kanye nezixhumi zezinhlelo zokulawula zezimboni, ezihlinzeka ngoxhumano lukagesi oluthembekile nempilo ende yesevisi.

Ama-Electrodes:

● Ngomshini wokukhipha ugesi (EDM), lapho ukuqhutshwa kwayo okuphezulu nokumelana nokugqoka kuqinisekisa ukususwa kwezinto ezibonakalayo ezinembile futhi eziphumelelayo.

● Kuma-electrode wokushisela ama-arc, anikeza ukuchithwa okuhle kokushisa nokuqina.

Izingxenye ze-Aerospace:

● Ezingxenyeni zezinjini zezindiza nezinhlelo zemikhumbi-mkhathi ezidinga izinto ezikwazi ukumelana nezinga lokushisa eliphezulu namandla emishini.

Ukuphathwa Kwezishisayo:

● Njengoba ukushisa kungena ezinsizeni zikagesi, ukuphatha kahle nokuqeda ukushisa.

Amathuluzi futhi Uyafa:

● Emisebenzini yokugxiviza nokwenza, ikakhulukazi ezinsizeni lapho ubulukhuni obukhulu nokumelana nokuguga kubalulekile.

Ubucwebe:

● Ngenxa yokubukeka kwayo okukhangayo nokuqina, ingasetshenziswa ekudaleni izingcezu zobucwebe ezikhethekile.

Isibonelo, embonini yezimoto, othintana nabo besiliva be-tungsten alloy basetshenziswa kuma-starter motors ukuze kuqinisekiswe ukuqala okuthembekile kwenjini ngaphansi kwezimo ezihlukahlukene. Emkhakheni wezokuxhumana, isetshenziswa ekushintsheni kwefrikhwensi ephezulu ukuze kugcinwe ubuqotho besignali kanye nokunciphisa ukulahleka kwesignali.

I-Silver Tungsten Alloy Properties

| Inombolo yekhodi. | Ukwakheka Kwekhemikhali % | Izakhiwo zemishini | ||||||

| Ag | Ukungcola≤ | W | Ukuminyana (g/cm3 ) ≥ | Ukuqina HB ≥ | I-RES (μΩ·cm) ≤ | I-Conductivity I-IACS/ % ≥ | TRS/ Mpa ≥ | |

| I-AgW(30) | 70±1.5 | 0.5 | Ibhalansi | 11.75 | 75 | 2.3 | 75 | |

| I-AgW(40) | 60±1.5 | 0.5 | Ibhalansi | 12.40 | 85 | 2.6 | 66 | |

| I-AgW(50) | 50±1.5 | 0.5 | Ibhalansi | 13.15 | 105 | 3.0 | 57 | |

| I-AgW(55) | 45±2.0 | 0.5 | Ibhalansi | 13.55 | 115 | 3.2 | 54 | |

| I-AgW(60) | 40±2.0 | 0.5 | Ibhalansi | 14.00 | 125 | 3.4 | 51 | |

| I-AgW(65) | 35±2.0 | 0.5 | Ibhalansi | 14.50 | 135 | 3.6 | 48 | |

| I-AgW(70) | 30±2.0 | 0.5 | Ibhalansi | 14.90 | 150 | 3.8 | 45 | 657 |

| I-AgW(75) | 25±2.0 | 0.5 | Ibhalansi | 15.40 | 165 | 4.2 | 41 | 686 |

| I-AgW(80) | 20±2.0 | 0.5 | Ibhalansi | 16.10 | 180 | 4.6 | 37 | 726 |