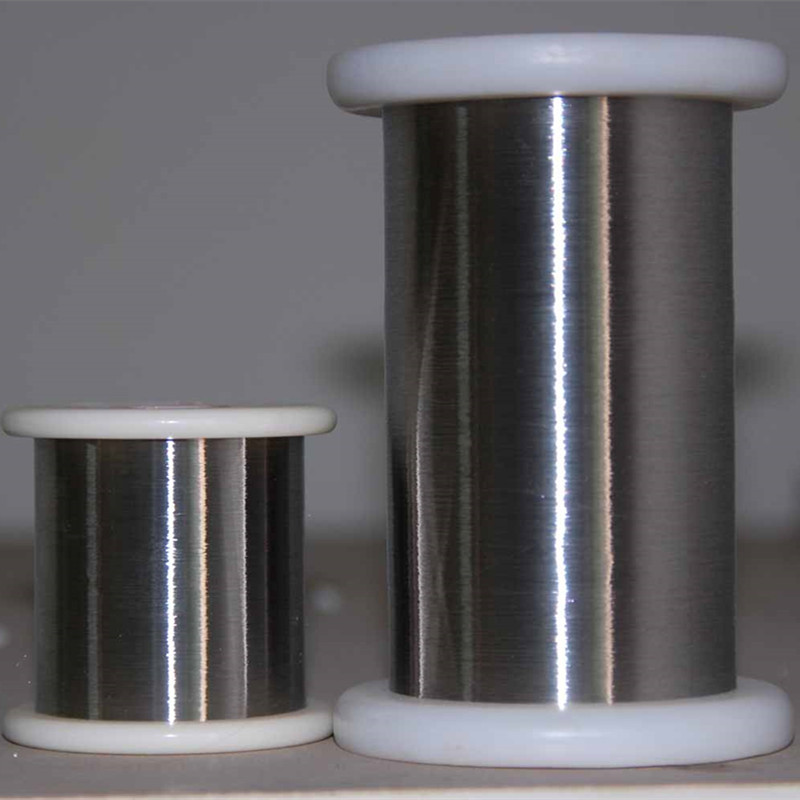

I-Nickel Chromium NiCr Alloy Wire

I-0.03mm Wire NiCr Alloy, 637 MPA Nickel Chromium Heating Wire, Ni90Cr10 NiCr Alloy

I-Ni90Cr10 iyingxubevange ye-nickel-chromium ye-austenitic elungele ukusetshenziswa kwezinga lokushisa elifinyelela ku-1250°C. Okuqukethwe kwe-chromium ephezulu (30% ngokwesilinganiso) kunikeza isikhathi esihle kakhulu sokuphila, ikakhulukazi ezinhlelweni zomlilo, sisetshenziswa kakhulu ku-vape, njengento yokushisa.

I-Ni90Cr10 ibonakala ngokumelana okuphezulu, ukumelana okuhle kwe-oxidation, i-ductility enhle ngemva kokusetshenziswa kanye nokushisela okuhle kakhulu. Ingxubevange ayikho ngaphansi "kokubola okuluhlaza" futhi ifaneleka kahle kakhulu ukunciphisa kanye ne-oxidizing atmospheres.

I-Ni70Cr30 isetshenziselwa ukushisisa izinto zikagesi ezithandweni zezimboni. Izinto ezisetshenziswayo ezijwayelekile yilezi: izithando zikagesi nezicwebezelayo, izifudumezi zokugcina izinto, iziko namahhanela anesimo sezulu esishintshayo.

Izicelo ze-NiCr Alloy Wires:

Izinto ze-nickel-chromium zinamandla okushisa aphezulu kanye nepulasitiki eqinile.

Isetshenziswa kakhulu kwiziko likagesi ezimbonini, izinto zikagesi zasendlini, amadivaysi e-infrared akude.

I-Nickel-chromium ne-iron, i-aluminium, i-silicon, i-carbon, isulfure nezinye izakhi zingenziwa zibe yi-alloy nickel-chromium wire ene-resistivity ephezulu kanye nokumelana nokushisa. Yisici sokushisa sikagesi sesitofu sikagesi, i-iron soldering kagesi, insimbi kagesi, njll.

Izinzuzo ze-Nickel-Chromium Wire:

Ukumelana kuphakeme uma kuqhathaniswa, ungqimba olungaphezulu lunokumelana okuhle kwe-oxidation, futhi amandla okucindezela agcinwa kangcono kunocingo lwe-iron-chromium-aluminium ngaphansi kokushisa okuphezulu kwemvelo yemvelo, futhi ukusebenza kwezinga lokushisa eliphezulu akulula ukukhiqiza ukubola. Intambo ye-nickel-chromium inokuguqulwa okuhle kwepulasitiki, izici ezinhle kakhulu zokucubungula kanye nekhono lokubumba, kulula ukuyikhiqiza nokuyicubungula, kulula ukuyilungisa futhi kunzima ukuyishintsha esakhiweni. Ngaphezu kwalokho, intambo ye-nickel-chromium inokukhipha umoya okuphezulu, ukumelana nokugqwala okuhle kanye nesikhathi eside sokufaka isicelo.

Amathebula okusebenza kwe-nickel-chromium alloy

| Izinto zokusebenza | I-Cr10Ni90 | I-Cr20Ni80 | I-Cr30Ni70 | I-Cr15Ni60 | I-Cr20Ni35 | I-Cr20Ni30 | |

| Ukwakheka | Ni | 90 | Phumula | Phumula | 55.0-61.0 | 34.0-37.0 | 30.0-34.0 |

| Cr | 10 | 20.0-23.0 | 28.0-31.0 | 15.0-18.0 | 18.0-21.0 | 18.0-21.0 | |

| Fe |

| ≤1.0 | ≤1.0 | Phumula | Phumula | Phumula | |

| Izinga lokushisa eliphezulu℃ | 1300 | 1200 | 1250 | 1150 | 1100 | 1100 | |

| Iphoyinti lokuncibilika ℃ | 1400 | 1400 | 1380 | 1390 | 1390 | 1390 | |

| Ukuminyana g/cm3 | 8.7 | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

| Ukungazweli |

| 1.09±0.05 | 1.18±0.05 | 1.12±0.05 | 1.00±0.05 | 1.04±0.05 | |

| μΩ·m,20℃ | |||||||

| Ukwelula ekuqhekekeni | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | |

| Ukushisa okuqondile |

| 0.44 | 0.461 | 0.494 | 0.5 | 0.5 | |

| J/g.℃ | |||||||

| I-Thermal conductivity |

| 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| KJ/mh℃ | |||||||

| I-coefficient yokunwetshwa kwemigqa |

| 18 | 17 | 17 | 19 | 19 | |

| a×10-6/ | |||||||

| (20~1000℃) | |||||||

| Isakhiwo se-Micrographic |

| I-Austenite | I-Austenite | I-Austenite | I-Austenite | I-Austenite | |

| Izakhiwo kazibuthe |

| I-Nonmagnetic | I-Nonmagnetic | I-Nonmagnetic | Uzibuthe obuthakathaka | Uzibuthe obuthakathaka | |