Ibha ye-Titanium Rod Titanium Alloy ehlanzekile

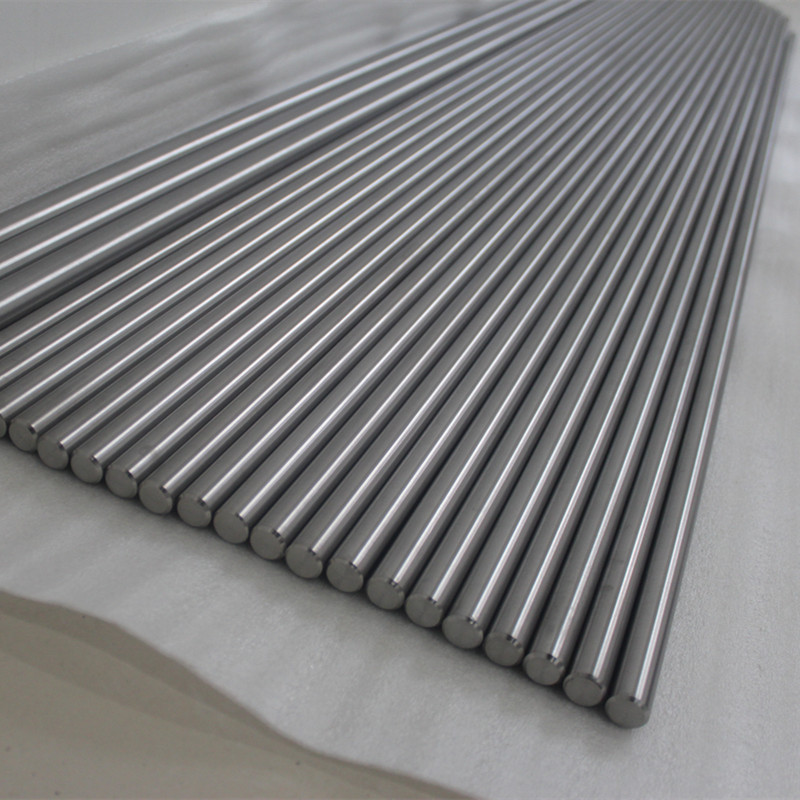

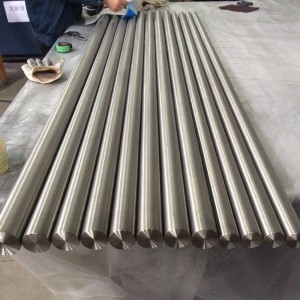

Incazelo

I-Titanium rod iyinto eluhlaza esetshenziselwa ukwenza i-titanium alloy ne-titanium metal. Inezici zokuminyana okuphansi, amandla aphezulu kanye nokumelana nokugqwala okuhle. Embonini ye-aerospace, i-titanium rod isetshenziswa kakhulu ekwenzeni izingxenye zesakhiwo sezindiza kanye nama-rocket nozzles; embonini yamakhemikhali, isetshenziswa njengesithwali se-catalyst kanye nedivayisi yokuhlanza ama-electrolyte; embonini yemishini, ingasetshenziswa njengesishintshi sokushisa kanye nempahla ye-condenser.

Embonini ye-metallurgical, induku/ibha ye-titanium isetshenziswa kakhulu ukukhiqiza insimbi ehlanzekile ehlukahlukene, insimbi engagqwali, insimbi engashisi nensimbi ekhethekile ye-alloy. Ngaphezu kwalokho, ibuye isetshenziselwe ukwenza amatshe ayigugu okwenziwa kanye namakristalu e-zircon arutile, amashidi e-ceramic e-piezoelectric embonini ye-elekthronikhi, kanye nokusakazwa okunembayo kobumo obuhlukahlukene.

I-Pure Titanium Rod / Titanium Alloy Bar Specifications

Ibanga le-Titanium Alloy:Gr.5, Gr.23, Ti-6Al-4v-Eli, TI5, BT6,Ti-6al-7Nb.

Ibanga Lezentengiso le-Titanium:Gr.3, Gr.4 ngokwentengiso okumsulwa.

Ibanga Lobubanzi:Ø5mm, Ø6mm, Ø8mm, Ø12mm, Ø14mm, Ø25mm, Ø30mm, njll.

Izinga Lokubekezelela:ISO 286.

Okujwayelekile:I-ASTM F67, ASTM F136, ISO 5832.

Ubude obutholakalayo:2.5 m ~ 3 m (98.4 ~ 118.1"), noma ngokwezifiso.

Ukuqonda:ephelele CNC machining.

Zonke izinti/amabha e-Titanium ne-Titanium Alloy anganikezwa ngobubanzi obungokwezifiso noma ubude, ukuze bulingane nezimfuneko zeKhasimende.

Izici ze-titanium alloy rods:I-elasticity enhle kakhulu, amandla aphezulu kanye ne-homogeneous microstructure.

I-Titanium Grade Iyatholakala

| I-ASTM B265 | I-GB/T 3620.1 | I-JIS H4600 | Okuqukethwe okubalulekile (wt%) | ||||||

| N,Ubukhulu | C, Max | H, Max | Fe, Max | O, Max | Abanye | ||||

| OkumsulwaI-Titanium | Gr.1 | TA1 | Ikilasi 1 | 0.03 | 0.08 | 0.015 | 0.20 | 0.18 | - |

| Gr.2 | TA2 | Ikilasi lesi-2 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | - | |

| Gr.3 | TA3 | Ikilasi lesi-3 | 0.05 | 0.08 | 0.015 | 0.30 | 0.35 | - | |

| Gr.4 | TA4 | Ikilasi lesi-4 | 0.05 | 0.08 | 0.015 | 0.50 | 0.40 | - | |

| I-TitaniumIngxubevange | Gr.5 | I-TC4I-Ti-6Al-4V | Ikilasi 60 | 0.05 | 0.08 | 0.015 | 0.40 | 0.20 | Al:5.5-6,75;V:3.5-4.5 |

| Gr.7 | TA9 | Ikilasi 12 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | Pd: 0.12-0.25 | |

| Gr.11 | I-TA9-1 | Ikilasi 11 | 0.03 | 0.08 | 0.015 | 0.20 | 0.18 | Pd: 0.12-0.25 | |

| Gr.23 | TC4 ELI | Ikilasi 60E | 0.03 | 0.08 | 0.0125 | 0.25 | 0.13 | Al:5.5-6.5;V:3.5-4.5 | |