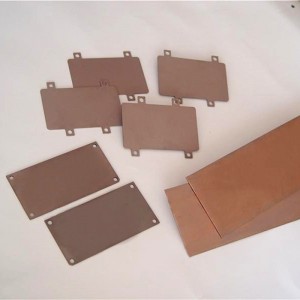

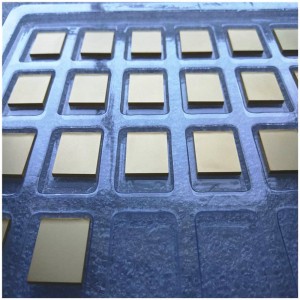

I-Tungsten Copper WCu Heat Sink

Incazelo

Izinto zokupakisha ze-Tungsten zethusi ze-elekthronikhi zinazo zombili izakhiwo zokunweba eziphansi ze-tungsten kanye nezakhiwo eziphakeme zokushisa ezishisayo zethusi. Okubaluleke kakhulu ukuthi i-coefficient yayo yokwandisa okushisayo kanye ne-thermal conductivity ingaklanywa ngokulungisa ukwakheka kwezinto okulethe ukukhululeka okukhulu.

I-FOTMA isebenzisa izinto zokusetshenziswa ezihlanzekile nezisezingeni eliphezulu, futhi ithola izinto zokupakisha ze-WCu zikagesi kanye nezinto zokucwilisa ukushisa ezisebenza kahle kakhulu ngemva kokucindezela, ukushisa okushisayo nokungena ngaphakathi.

Izinzuzo ze-Tungsten Copper (WCu) Electronic Packaging Materials

1. Izinto zokupakisha ze-electronic ze-tungsten zethusi zine-coefficient yokwandisa ukushisa okuguquguqukayo, engakwazi ukufaniswa nama-substrates ahlukene (njengalezi: insimbi engagqwali, i-valve alloy, i-silicon, i-gallium arsenide, i-gallium nitride, i-aluminium oxide, njll.);

2. Azikho izici zokuvula i-sintering ezingeziwe ukuze kugcinwe ukuqhutshwa kahle kwe-thermal;

3. I-porosity ephansi kanye nokuqina komoya okuhle;

4. Ukulawula usayizi omuhle, ukuphela kwendawo kanye nokucaba.

5. Nikeza ishidi, izingxenye ezakhiwe, futhi zingahlangabezana nezidingo ze-electroplating.

I-Copper Tungsten Heat Sink Properties

| Ibanga lezinto ezibonakalayo | Okuqukethwe kwe-Tungsten Wt% | Ukuminyana g/cm3 | Ukunwetshwa kwe-Thermal × 10-6I-CTE (20℃) | I-Thermal Conductivity W/ (M·K) |

| 90WCu | 90±2% | 17.0 | 6.5 | 180 (25℃) /176 (100℃) |

| 85WCu | 85±2% | 16.4 | 7.2 | 190 (25℃)/ 183 (100℃) |

| 80WCu | 80±2% | 15.65 | 8.3 | 200 (25℃) / 197 (100℃) |

| 75WCu | 75±2% | 14.9 | 9.0 | 230 (25℃) / 220 (100℃) |

| 50WCU | 50±2% | 12.2 | 12.5 | 340 (25℃) / 310 (100℃) |

Ukusetshenziswa kweTungsten Copper Heat Sinks

Izinto ezifanele ukupakishwa ngamadivaysi anamandla amakhulu, njengama-substrates, ama-electrode aphansi, njll.; amafreyimu okuhola aphezulu; amabhodi okulawula ukushisa okushisayo kanye nama-radiator emishini yezempi neyomphakathi yokulawula ukushisa okushisayo.