Amathagethi e-Tungsten Sputtering

Amathagethi e-Tungsten Sputtering

Okuhlosiwe kwe-Tungsten sputtering kudlala indima ebalulekile ezinhlelweni ezihlukahlukene zesimanje zobuchwepheshe. Lezi zinhloso ziyingxenye ebalulekile yenqubo ye-sputtering, esetshenziswa kakhulu ezimbonini ezifana ne-electronics, i-semiconductors, ne-optics.

Izakhiwo ze-tungsten zikwenza kube ukukhetha okuhle kokuhlosiwe kwe-sputtering. I-Tungsten yaziwa ngendawo yayo yokuncibilika ephezulu, ukuqhutshwa kwe-thermal okuhle kakhulu, kanye nomfutho we-vapor ophansi. Lezi zici ziyivumela ukuthi imelane namazinga okushisa aphezulu kanye nokuqhuma kwezinhlayiyana ezinamandla phakathi nenqubo yokufafaza ngaphandle kokuwohloka okukhulu.

Embonini yezogesi, okuhlosiwe kwe-tungsten sputtering kusetshenziselwa ukufaka amafilimu amancanyana kuma-substrates ukuze kwenziwe amasekhethi ahlanganisiwe namadivayisi amancane kagesi. Ukulawulwa okunembile kwenqubo ye-sputtering kuqinisekisa ukufana kanye nekhwalithi yamafilimu afakiwe, okubalulekile ekusebenzeni nokuthembeka kwezingxenye ze-elekthronikhi.

Isibonelo, ekukhiqizweni kwezibonisi zephaneli eyisicaba, amafilimu amancanyana e-tungsten afakwa kusetshenziswa okuhlosiwe kwe-sputtering anomthelela ekusebenzeni nasekusebenzeni kwamaphaneli wokubonisa.

Emkhakheni we-semiconductor, i-tungsten isetshenziselwa ukudala ukuxhuma kanye nezingqimba zokuvimbela. Amandla okufaka amafilimu e-tungsten azacile navumelanayo asiza ekwehliseni ukumelana nogesi futhi athuthukise ukusebenza kwedivayisi kukonke.

Izinhlelo zokusebenza ze-Optical nazo ziyazuza ekuhlosweni kwe-tungsten sputtering. Izembatho ze-Tungsten zingathuthukisa ukubukeka nokuqina kwezingxenye ze-optical, njengezibuko namalensi.

Ikhwalithi nokuhlanzeka kokuhlosiwe kwe-tungsten sputtering kubaluleke kakhulu. Ngisho nokungcola okuncane kungathinta izakhiwo nokusebenza kwamafilimu afakiwe. Abakhiqizi basebenzisa izindlela eziqinile zokulawula ikhwalithi ukuze baqinisekise ukuthi okuhlosiwe kuhlangabezana nezidingo ezidingekayo zezinhlelo zokusebenza ezahlukene.

Izinhloso ze-Tungsten sputtering zibalulekile ekuthuthukisweni kobuchwepheshe besimanje, okuvumela ukudalwa kwamafilimu amancanyana ekhwalithi ephezulu aqhuba ukuthuthukiswa kwezinto zikagesi, ama-semiconductors, ne-optics. Ukuthuthuka kwabo okuqhubekayo kanye nokuqanjwa okusha akungabazeki ukuthi kuzoba neqhaza elikhulu ekulolongeni ikusasa lalezi zimboni.

Izinhlobo Ezihlukene Zokuhloswe Kwe-Tungsten Sputtering kanye Nezicelo Zazo

Kunezinhlobo eziningana zokuhloswe kwe-tungsten sputtering, ngayinye enezici zayo ezihlukile kanye nokusetshenziswa kwayo.

Okuhlosiwe Okuhlanzekile kwe-Tungsten Sputtering: Lezi zakhiwe nge-tungsten emsulwa futhi zivame ukusetshenziswa ekusetshenzisweni lapho indawo ephezulu yokuncibilika, i-thermal conductivity enhle kakhulu, kanye nomfutho we-vapor ophansi kubalulekile. Bavame ukuqashwa embonini ye-semiconductor ukuze bafake amafilimu e-tungsten ukuze kuxhunywe izingqimba zokuvimbela. Isibonelo, ekukhiqizeni ama-microprocessors, i-tungsten sputtering ehlanzekile isiza ukudala ukuxhumana okuthembekile kukagesi.

Amathagethi e-Alloyed Tungsten Sputtering: Lokhu okuqondisiwe kuqukethe i-tungsten ehlanganiswe nezinye izici ezifana ne-nickel, i-cobalt, noma i-chromium. Amathagethi we-tungsten ahlanganisiwe asetshenziswa lapho kudingeka izakhiwo ezithile zezinto ezibonakalayo. Isibonelo sisembonini ye-aerospace, lapho i-alloyed tungsten sputtering target ingase isetshenziselwe ukudala ama-coatings ezingxenyeni ze-turbine ukuze kuthuthukiswe ukumelana nokushisa nokumelana nokuguga.

Okuhlosiwe kwe-Tungsten Oxide Sputtering: Lezi zisetshenziswa ezinhlelweni lapho kudingeka khona amafilimu e-oxide. Bathola ukusetshenziswa ekukhiqizweni kwama-transparent conductive oxide wezibonisi zesikrini esithintwayo namaseli elanga. Ungqimba lwe-oxide lusiza ekuthuthukiseni ukuguquguquka kukagesi kanye nezakhiwo ze-optical zomkhiqizo wokugcina.

I-Composite Tungsten Sputtering Target: Lezi zihlanganisa i-tungsten ehlanganiswe nezinye izinto esakhiweni esiyinhlanganisela. Zisetshenziswa ezimeni lapho inhlanganisela yezinto ezivela kuzo zombili izakhi ifunwa. Isibonelo, ekuhlanganisweni kwemishini yezokwelapha, i-tungsten eyinhlanganisela ehlosiwe ingase isetshenziselwe ukwakha i-biocompatible nehlala isikhathi eside.

Ukukhethwa kohlobo lwethagethi ye-tungsten sputtering kuncike ezidingweni ezithile zohlelo lokusebenza, okuhlanganisa izakhiwo zefilimu ezifunwayo, impahla engaphansi, nezimo zokucubungula.

Isicelo se-Tungsten Target

Isetshenziswa kakhulu ekuboniseni iphaneli eyisicaba, amaseli elanga, amasekhethi ahlanganisiwe, ingilazi yezimoto, i-microelectronics, inkumbulo, amashubhu e-X-ray, imishini yezokwelapha, imishini yokuncibilika neminye imikhiqizo.

Ubukhulu be-Tungsten Target:

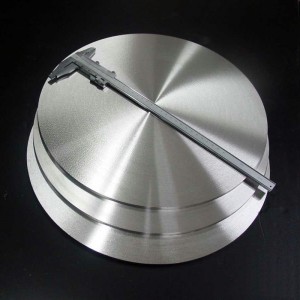

I-Disc target:

Ububanzi: 10mm ukuze 360mm

Ubukhulu: 1mm kuya ku-10mm

Ithagethi ehleliwe

Ububanzi: 20mm ukuze 600mm

Ubude: 20mm ukuze 2000mm

Ubukhulu: 1mm kuya ku-10mm

Ithagethi ye-Rotary

Ububanzi bangaphandle: 20mm kuya ku-400mm

Ubukhulu bodonga: 1mm kuya ku-30mm

Ubude: 100mm ukuze 3000mm

I-Tungsten Sputtering Target Specifications:

Ukubukeka: isiliva esimhlophe esicwebezelayo sensimbi

Ubumsulwa: W≥99.95%

Ukuminyana: ngaphezu kuka-19.1g/cm3

Isimo sokuhlinzekwa: Ukupholisha ubuso, ukucutshungulwa komshini we-CNC

Izinga lekhwalithi: ASTM B760-86, GB 3875-83